Blog Archives

50 Years Ago……….

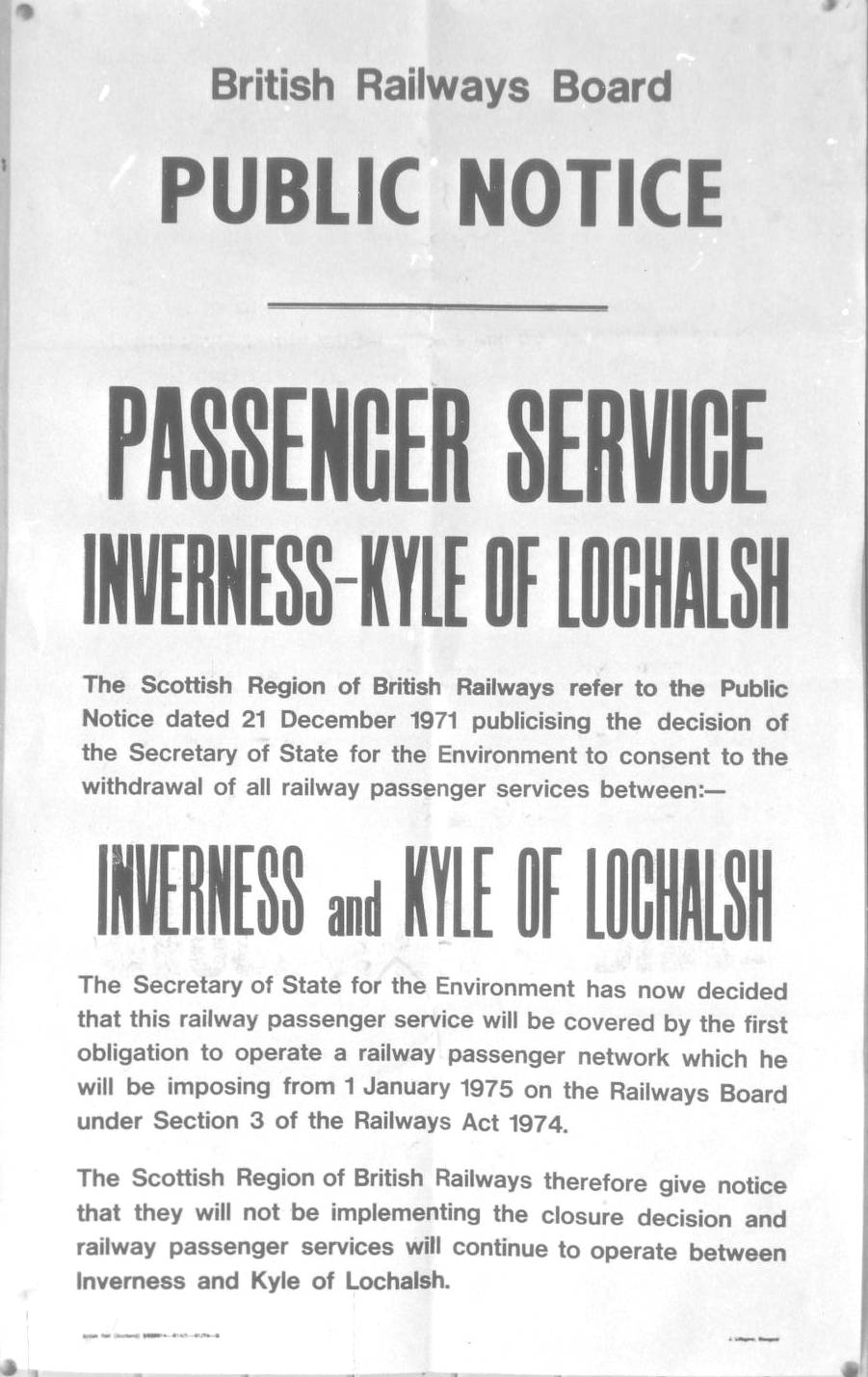

In 1974, after facing years of closure threats, the Kyle line was finally given a final repreive.

I thought it ought to be remembered.

Oddly, the supposed reason for the repreive was the increased freight traffic associated with the oil industry at Kishorn. This never proved as abundant as hoped but by the time this was realised, the social impact that the closure would cause had become sufficiently political that the line has not been seriously threatened with closure since.

Delayed Delivery – Part 2

Once the basic structure of the gantry is in place, the real task of making the signals signally commences. First up were the smoke deflectors and the brackets for the balance weights. Also fitted are the main portions of the fan route indicator, but that will be explained further once I get it going!

For the arm bearing point and lamps I am using some 3D prints produced by Steve Hewitt and available from Shapeways. They can be found here https://www.shapeways.com/product/JJRSB … arketplace. They are fairly expensive but they are neat and save a lot of manufacture. There is, however, a but – they are very delicate and I am very fearful of thier long term durability. I am highly likely to draw some of my own up and get them cast in lost wax. It will make them even more expensive but I have about a 50% casualty rate at the moment, so maybe in the long term it will be cheaper!

The arms are Masokits, these are definitely the best available arms for LMS/LNER/BR semaphores. This is especially true of the minature shunt arms as the MSE ones are simply too delicate to bother with (imagine how do I know that………….!). So this is where we are now at with the arms mounted temporarly on the bearings.

There are five movements in the down direction (three of which operate via the route indicator) and then a pair in the up direction – hence the back to front arms.

The plates at the top of the dolls are mounting points for ladders. It transpires they are wrong and have already gone!

So the intensity level has dialled up a notch with these portions (especially breaking the bearing/lamp fittings) but it really gets interesting when you try and make these things work.

I don’t know myself yet (although I know for the couple of arms I have finished, so I have an inkling), but i think it might be fun to have a little sweepstake on how many moving parts there will be in the finished gantry. Five arms, three fan route indicators and each is operated by way of angle cranks. Each arm, crank and intermediate wire counts as a moving part, as do the servos………………..guesses please?

Delayed Delivery – part 1

After a long pause, caused by that irratating thing called life getting in the way, I am looking to deliver on some long made modelling promises over the holiday season.

The major task is a rather full on gantry signal with no less than eight movements on it (which is an improvement, when initially designed it had nine!), including a rather natty fan route indicator. This is for a friend’s layout and is in return for some signal cabins that he built no less than 15 years ago – I told you the promises were long made! Mind you, he hasn’t got the layout fully running yet, so I am still ahead of him!

The gantry spans only two lines so it can be formed with channel section. There are good drawings and pictures in LMS Journal no 5 of this. I have made mine from milled brass section and then the landing was a custom etch I designed as it takes a surprisingly large amount of material and effort to construct this from scratch. These etches included the doll base plates although the dolls have a thickened tube at the lower level which of course I forgot and had to undo later work to put on!!

The signal is to be located on an embankment which meant that I could not simply put flat base plates on the foot of the gantry columns. Instead I have constructed a housing that matches the slope of the embankment and then the baseplates are partially sloped to match this with square sections representing the foundations of the prototype columns. Below these baseplates I have then formed housings to take the servos which will eventually operate the arm actions.

So far, this is pretty easy modelling (although I lost a number of drill bits opening up the stanchion positions on the landing – grrrrrr!). The tough bit comes next……………

There are potentially two viewers of this thread who might be thinking that I have long outstanding modelling promises to them too……………I am also working on one of these too!!

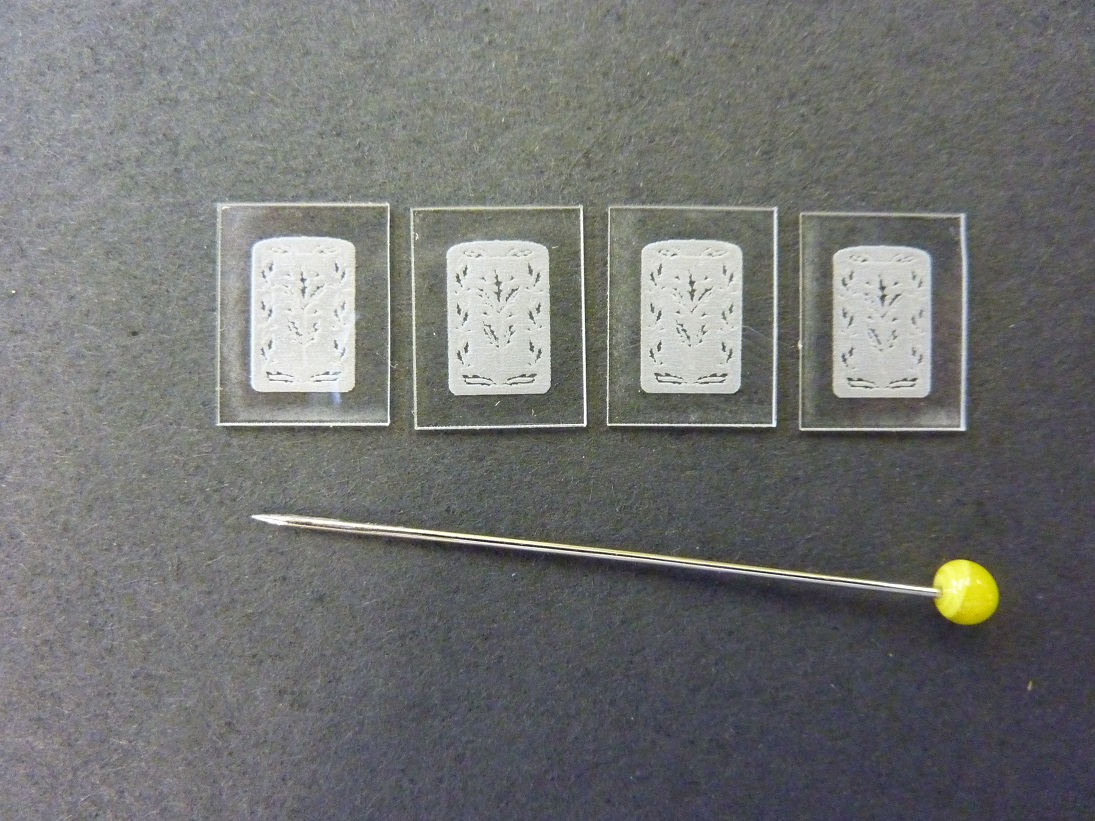

News from Miscellany Models

With the assistance of Duncan Petford, Miscellany Models are now offering engraved glass windows featuring the thistle emblem that the Highland used to obscure the windows of toilet compartments. They come in packs of five, for £7 postage included and are available here.

These are laser engraved on 1mm perspex and really lift the appearance of a Highland coach, as you can see:

Sadly, I have also had to increase the prices for most of the products. The costs of the last few deliveries from my etchers have been eyewateringly expensisve, so I need to defer a degree of this. The good news is that this is an indication that more products will soon be featured too – so Highland and LMS modellers keep an eye out.

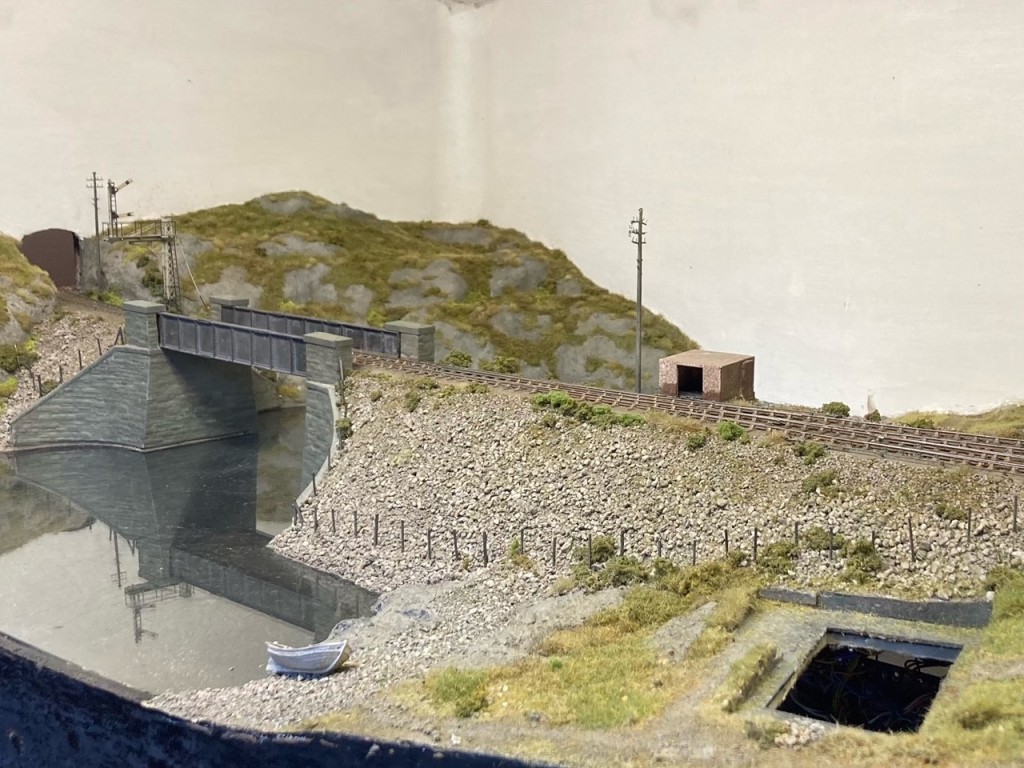

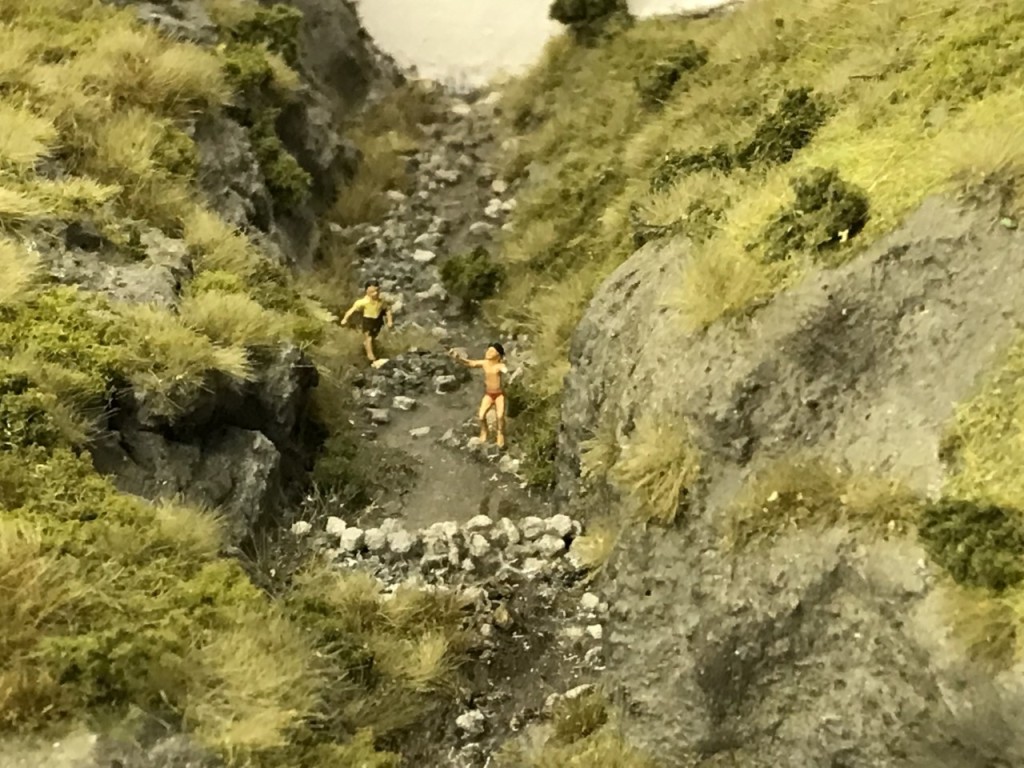

Portchullin Goes Green………….Again

Fear not, this is not an announcement that the McRats have been converted from DCC to run on ethanol (although this remains the preferred fuel of the layout’s operators). Instead it is a recognition that after 13 years on the exhibition circuit, Portchullin was getting a little faded and even battered. The colours of the vegetation were fading and the woodwork was showing all the miles they have been lugged about in the back of a van – all in all it was looking like 1970s BR, just not in the right way.

We reached the conclusion that something needed to be done about it and in anticipation of an April exhibition invite, the gang arranged a session on the layout to give it a spring refresh. Sadly the show had become a covid casualty by the time we met up but we convened anyway and even the stone-cold hearted Pete was showing emotion at seeing us all again by insisting on greeting us all with a hug!

So out came the static grass machine, modge podge and various scenic materials and away we went…….

We ended up making quite a lot of difference in only a short while, but adding the dwarf bushes and other vegetation then took a lot of time and I am still thinking it needs more attention.

There remains a lot to do, including a revamp of all of the woodshell and lighting gantry, but the layout is looking a lot fresher.

The other main task in hand is a complete rewire. Too often we (well I, the others will have nothing to do with my wiring) have had heads under the baseboard trying to sort out either point-motors or errant wiring, it has to change!

The Polytechnic Special Excursion Train

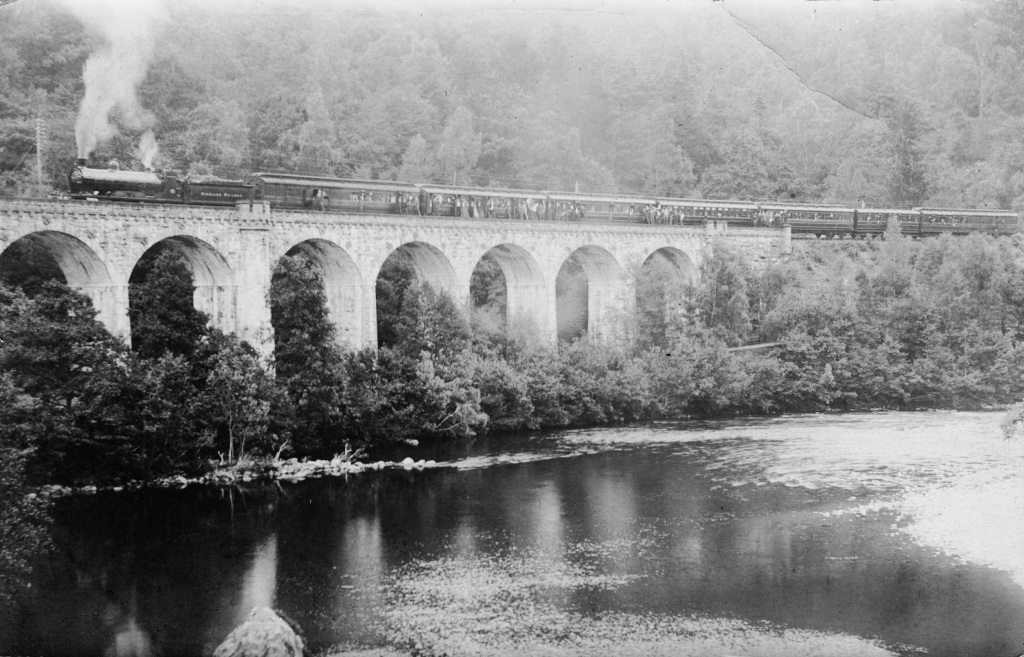

From time to time, I see photographs that are intriguing or catch the imagination. This week generated one such example that I felt was worth sharing. In addition to being a rather wonderful timepiece of Edwardian travel, this view of a Highland Railway series 1 castle on the viaduct at Killiecrankie prompts a number of interesting discussion points.

Dealing with the purely railway one first; the constitution of the train. This is largely made up of East Coast Joint Stock coaches from the early part of the last century, supplemented by a Great Northern dining car and one NER coach. The East Coast Joint Stock Co was a joint undertaking of the three companies that made up the east coast route from Kings Cross to Scotland to provide coaching stock that could run across three company’s lines. Back in 2016, I showed my part build of a very similar coach to those on the viaduct for you to compare. By the way, before long there will be a further instalment in this series, as I have made progress with it and have a pretty much finished coach.

What initially surprised me was that all of the stock was third class; which was very unusual for trains of this time when railway travel was proportionally much more expensive and thus attracted the “monied classes” rather more than today. My colleagues in the Highland Railway Society of course not only had the answer for this but there was even an article on it in their journal a few years back written by John Roake. The train is obviously a special rather than a day to day timetabled service and it transpires that it was one of a series organised by the Polytechnic Touring Association in the beginning of the 20th century. This organisation had its origins as a travel society of the Regent Street Polytechnic (which has developed into the University of Westminster) who arranged tours within the UK, Europe and further afield for its students before subsequently becoming and independent business in its own right. In time, it became a fully fledged travel business and once it had merged with a firm called Sir Henry Lunn Ltd, became a household name to people of my generation – Lunn Poly (now part of Tui).

From around 1901 rail tours of the Scottish highlands were organised in specially commissioned services across the summer season. These were advertised as “a week in bonny Scotland for three guineas“. This was equivalent to a month’s average wage at the time, so even though the service was not in luxurious first class, it was hardly for the masses either. This is rather evidenced by the finery of both the ladies and gentlemen that are visible in the picture. The tour visited a number of Scottish beauty spots, often combined with a steamer trip to complete a round circuit or, as in this case a walk through the scenery to Dunkeld. Dunkeld is 16 miles from Killiecrankie, so they got a fair share of exercise!

The picture is a posed shot and is likely to be an official view for publicity purposes and what caught my eye was the participants standing on the viaduct’s parapet. The viaduct is 54 feet high, so these people are standing about seven stories up on an ledge that is a foot or so wide! Can you imagine the health and safety police sanctioning that now? Mind you, when you look closely at the picture you can see that many of them are leaning gingerly back on the carriage stock – so it appears that they were not oblivious of the fall!

And to sign off, this is an image from about the same place approximately 80 years later in July 1985; a class 47 on what is probably the northbound Clansman service from London Euston (photo by Eastwood 4117). The trees have gown up somewhat in the intervening years – as they have since, the view is largely obscured now but the walk along the river is still worthwhile if you are in the area.

Normal Modelling Will Resume Soon…..

Sorry for the absence of any posts for rather a long time………..

We decided to move house, for a few reasons (a pleasant side effect of which is I can build myself a larger railway room) and this has been nearly all consuming for a few months. We are now moved and whilst we remain surrounded by boxes, normality is slowly returning to our life.

So some modelling posts soon, but first a summer holiday!

A Fold of Cattle Wagons

Your pub quiz fact for the day is that the collective name for Highland cattle is not a herd, as it would be for most cattle. Instead, and only for Highland cattle, the collective name for a group of cattle is a fold. If that does come up in a pub quiz, you owe me a pint!

Cattle were an important part of the highland economy and hence were a good source of income of the Highland Railway. In my slightly distorted version of real history, there were 4 million head of cattle to transport per annum in the Glenmutchkin area (which is remarkable given the cattle population of the entire UK at the time was only a little bit higher!). Thus, a fold of cattle wagons was obviously a pre-requisite for Glenmutchkin and this is what I have been working on of late.

First up are a pair of LMS standard cattle wagons; to diagram 1661. These date from 1925; so they would have been fairly new at the time that my layout is set in. These were built from Parkside plastic kits with only moderate modifications around the break gear and, of course, some sprung w-irons. Being a relatively recent kit, it is generally very good and whilst it is possible to convert it to some alternative variants, these came later than my modelling period so I was not tempted. I am concerned that I have painted them rather to dark though, so I will be weathering them on the light side.

Next up is a Great North of Scotland Cattle wagon, from a Model Wagon Company white metal kit. This is a much older kit and didn’t it felt it! For reasons I am not certain of, the two sides were not the same length so in practise the body is a bit trapezoidal – but can you tell? The casting was also covered in flash which was a particular problem in the gaps between the wooden slats – this meant I spent a few hours I would sooner not have spent scraping it out to keep these clear. The GNoS vehicle was a much more basic vehicle and, strangely, did not get any large ownership lettering so they remained rather anonymous, Instead, they had simple cast plates, which I made from a locomotive number plate and dry brushed white on the letters. I have glossed over the fact it does not have the right number or even a consistent number from one side to the other – sod the “getting it all right” mantra!

I have also built a further Highland cattle wagon, built from a Model Wagon Company kit. This is the Drummond era version and I have already built a number of these so this was relatively routine – its just as well as there are still a couple in their packet waiting their turn!

The final cattle van is a David Geen kit for the L&Y large cattle wagon. Whilst still a whitemetal kit, it is of somewhat better quality than both the Model Wagon Co kits so was rather easier to make. Even then, it did need filling at the corner joints and I felt the need to swap the brake levers for replacements – why to even the better manufacturers use the same material for all of their kits?

To finish of this little rake, I obviously need another brake van. This is not so obvious because this is brake van no 11 in the collection and I know I have at least one more spirited away! Whilst this was a kit build, it was first a kit unassemble as this was a vehicle I had first built in my teens. Generally fairly well but a couple of bits had got damaged over the years so I felt it needed rejuvenating.

And here they all are on parade.

Now all I need is rather a lot of heilen coos to fill them up with. I have been working on this but it seems that resin casting is a tad more difficult than I thought……………..

Oh and yes, they are all way to clean; another weathering sess’ is required guys………..

19 August 1870

This day, 150 years ago, was a significant one for the highlands and the western isles. It marked the opening of the first railway to reach the Atlantic north of Helensburgh. To understand how significant this was, take a look at a map and and see what proportion of the country this represents – its almost a third of the country.

The line at the time was called the Dingwall and Skye Railway but nowadays we know it a little better as the line to Kyle of Lochalsh. Given it is the primary inspiration for my layouts, I think this anniversary needs to be marked with a blog post!

The original name of the line gives away the objective of the promoters – to bring communication to the western side of Scotland, in particular the islands such as the Isle of Skye. Given that even in the 19th century the centre of the country was very sparsely inhabited, the population was concentrated on the coastal fringes and on the islands. Prior to the arrival of the railway, to ship goods or travel to the islands from the lowlands would take days. These poor communications inhibited the development of these parts and the arrive of the railway was a major spur to the prosperity of the region.

Despite the value to the region, the line was not constructed with the support of the government, instead it come about entirely with private finance. Given the sparseness of population, this was a brave venture and the promoters did not have sufficient money to reach their ultimate destination – the Atlantic seaboard. Instead they only just managed to reach a long finger of a sea-loch, Loch Carron. This was only intended to be a temporary solution to allow some income to be generated before the final push for the eventual terminus to be made. As with the best of plans, it too a long time for this ambition to be realised as the line to the present terminus at Kyle of Lochalsh did not come to be for a further 27 years.

The line started from the route up the east cost of the northern part of Scotland from Ross & Cromarty’s county town, Dingwall. It was intended to run through a fairly significant spa town, Strathpeffer, but this plan was foiled by an obstinate landowner. Perversely, therefore, the line bypassed the most significant town on the route, which hardly helped its finances! Whilst the line then travelled through sparse countryside with few centres of population, there were a series of roadheads where glens branch off. A feature of the line until the 1980s were buses coming to meet each train to provide links to the other parts of the west.

The line is a remarkable survivor as it was chalked up for closure on several occasions. Its most significant saviour was the oil industry in the mid 1970s, when the country’s biggest dry dock was built not far away at Loch Kishorn and the prospect of increased traffic persuaded the government to refuse a closure request. This prompted the railway to make efficiency savings; for example the line was the first example to use a radio signalling system 40 years ago.

The line survives to today in its extended form to Kyle of Lochalsh and (touch wood) seems to be safe for a long term future. Ok, it has a lot less charm as a railway than it used to but the scenery is still second to none and you still have the romance of heading to the wild west of Scotland – it justifies being seen as one of the worlds great railway journeys! If you have never done it, then it really needs to make your bucket list!

If you want to enjoy the charm of the line in the era that Porthcullin is set, this is a link to a fabulous video created by Ross & Cromarty council in 1972. This was deliberately rose tinted as it was a promotional tool to seek to convince the then government not to allow its closure – indeed, it was shown to parliament at the time and may even have had a hand in the saving of the line. After all, you don’t just arrive at magic, it has to be conjured…….

As an alternative, if you do want to find out more about the line there are a number of good books on the line; including one by my father I mentioned here.

Fuel for Thought

Obviously, where there is water in a locomotive yard, there really ought to be coal too.

The Highland, like many other railway companies of the time (certainly the Scottish ones), sought to stockpile coal. This was presumably insurance against coal strikes and allowed them to purchase coal at times when the price was favourable. Thus, quite substantial coal stacks where very much a feature of shed areas in the pre-grouping era. Typically, these were arranged in engineered stacks, with the sides formed in “dry-coal walling” and then loose coal behind. I can’t recall ever seeing this modelled, so I though I would change that!

The actual structure of the loading bank was formed in plasticard and Wills random stone sheets, but with the mortar courses softened as I described for the water towers. The shape of the coal stack was formed with a piece of house insulation left over from a DIY job and then real coal used to form the effect of…..err……real coal. Actually, real coal does not look quite like real coal without a bit of effort. It does shatter into angular but irregular lumps like real coal (especially if lignite coal is used) but its glossiness does not scale down. However, a vigorous brush with generous amounts of soot black weathering powder takes the gloss back and the whole becomes quite convincing. You do feel as if you are going to get pretty filthy if you go up onto the bank – and until the whole is fixed with matt varnish, you would!

Individual coal chunks were glued in place to form the wall structure. To get the effect, it is not enough to simply scatter the coal onto a bed of glue each chunk has to be laid individually with care taken to lock it into the course below – just like a real dry stone wall. Thus, the vertical walls of this took about a day to complete, scattered over about 8 stints because it is necessary to let the glue dry after every couple of courses to stop the layers collapsing. It is then possible to scatter the loose material behind the walls onto a layer of glue – the above picture shows the contrast in effects between the two methods.

But it is hard work shovelling coal into tenders, especially as the locos got larger and their tenders higher. As befitting such an important place as Glenmutchkin, it has all the modern amenities for coaling engines, a hand crane and a large bucket! In this case, I have fitted servos to this so that it operates – partly as a bit of fun and also to slow things down in the yard to a more realistic pace without it getting too boring for the viewer.

The crane operation was achieved by way of three servos – one to rotate it and then one each for the front and rear of the coal bucket. These are all mounted onto a cradle that is rotated by the former – thus as the crane rotates so too do all the servos and there is a quadrant shaped slot in the base to the rear of the post (just visible in the picture above) that allows the cables to rotate too without snagging.

The cradle is mounted to a solid rod that is in turn secured to the actual crane. This then slides into the rod that can be seen projecting from the base in the picture above. This means that there is limited strain on the crane or the mount as I had feared it might otherwise snap with any heavy-handedness on my part (something I am prone to!). The rest of the crane was made with brass hollow section and pulley wheels from Bill Bedford. A series of guides were made of small section tube on the pulley wheels, at the winding drum and across the jib to retain the operating cables.

The bucket was fashioned from metal sheet and is filled with low melt solder to give it as much weight as possible. It is secured to the servo arms with invisible thread – which is a nylon seamstresses material used for making invisible stitches. It comes in both clear (which really is invisible) and black, I used the latter. It is much better than cotton thread as that has a furry finish that looks terrible after a time or if it is painted. It is, however, very fine and rather wriggly to knot, so using it involves a certain amount of cussing!

And this is what it looks like in operation…………

A little of the bouncing about of the bucket is caused by it sitting on my servo test rig, so the act of changing the switches imparts a little vibration. Hopefully, when mounted on the layout this will be less obvious.

I do still need to do the final detailing on this; tools, a bit of discarded debris and a couple of fellas from Modelu standing around doing nothing (because static people in animated poses look silly on a model layout!).